Unitronics One Integrated Solution for Control and Automation

Customer Challenge

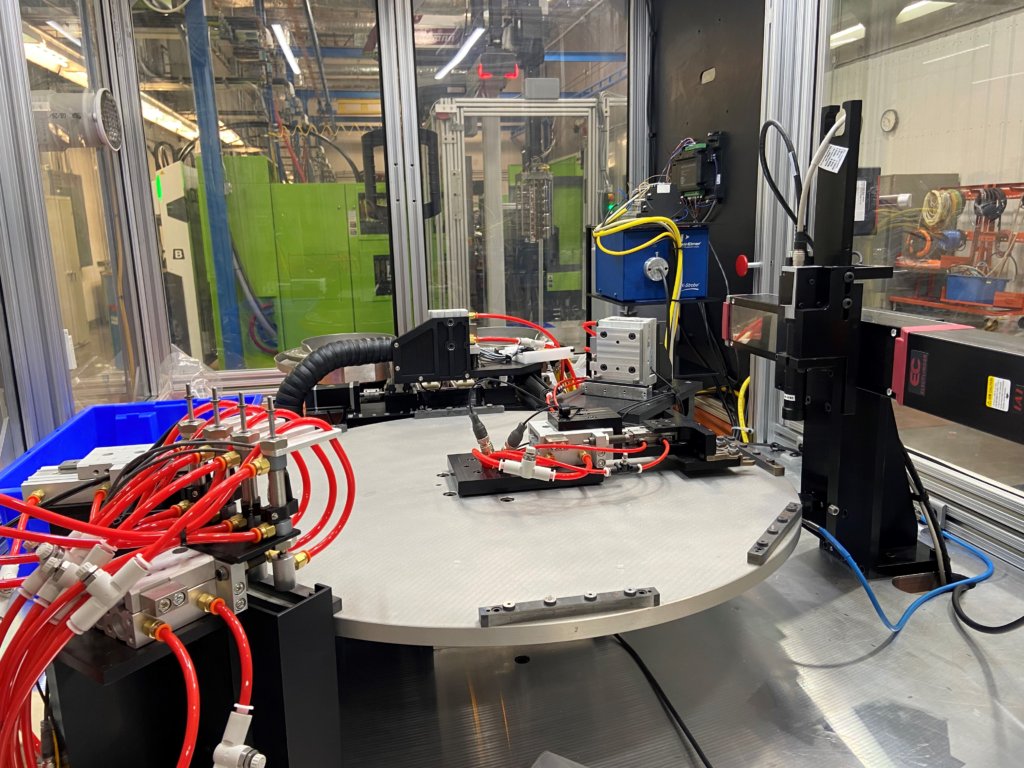

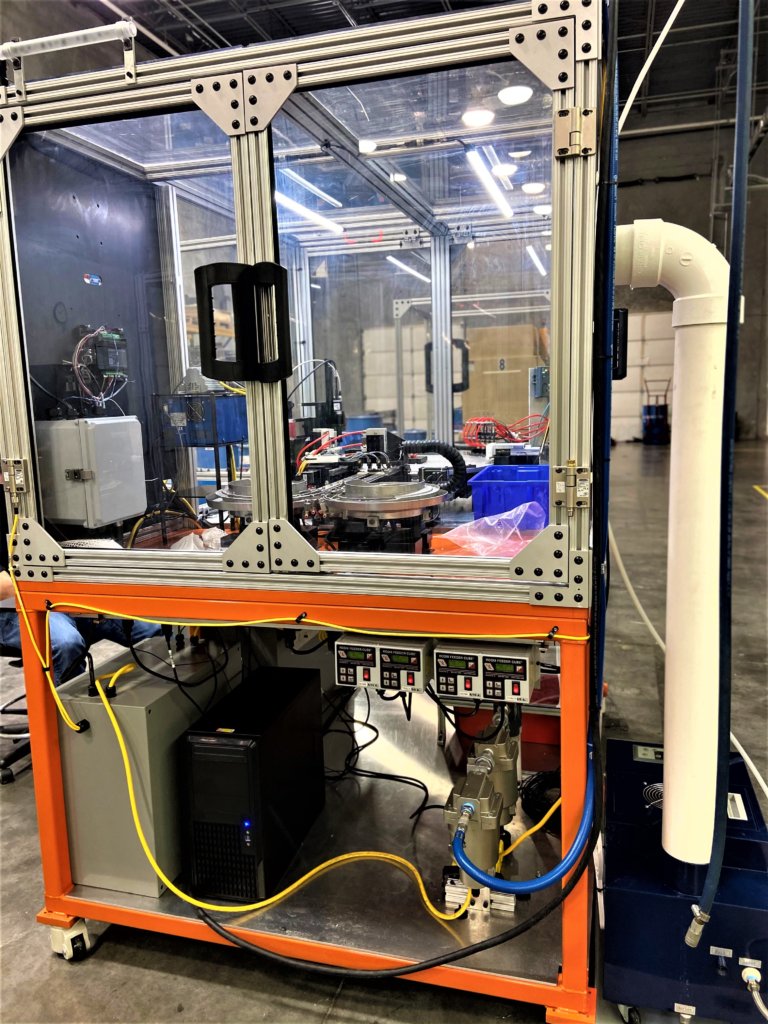

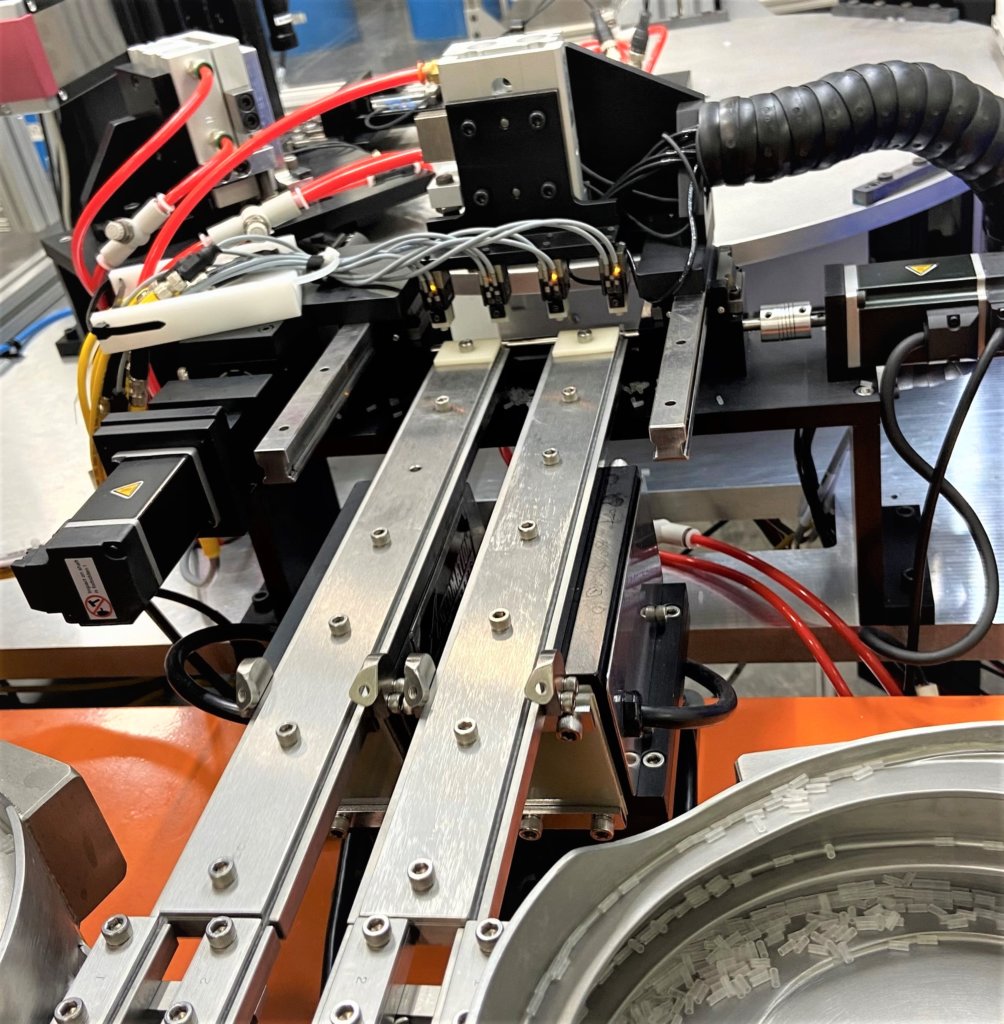

A rubber parts manufacturer has an inspection machine with multiple inspection stations for a single rubber part. The rubber parts have a cut made all the way through them at one station, then the cut is inspected by cameras for accuracy at the next station and at the final station the blower keeps the parts that pass the inspection and removes the parts that fail. The rubber parts must pass through all the stations successfully to be kept in production. In order to operate the inspection station our customer needs a PLC, HMI, I/O, Servo drive and Motors that all easily integrate and communicate with one another. The customers current product solution is multi-vendor. The integration of the HMI, PLC, Servo Drives and Motors to communicate has created a frustration point, with high time and effort costs at every stage of the product collaboration process. This customer also frequently makes changes to stations adapting them to new parts that are being tested, further amplifying the need for ease of use and simplified programming moving forward.

As demonstrated in the video below, the rubber parts start out in the bowl loaders, a servo motor is needed to move the slide to take parts from the bowl loaders and load them into the dial table. A second servo motor is needed to rotate the rotary nest, that holds the loaded rubber parts, 90 degrees every machine cycle. The motion control elements on this application require a Servo with precision and speed to properly grip the rubber parts and place them in the rotary nest.

A-tech Solution

The experienced Automation Sales staff at A-tech were able to find the best solution for our customer with the Unitronics’ One Integrated Solution. An end to end motion control solution comprising of a PLC + HMI + I/O + Servo + VFD + related components, all programming and troubleshooting can be done at once, in the Unitronics All-in-one software environment. This shortens the learning curve and simplifies workflow and integration.

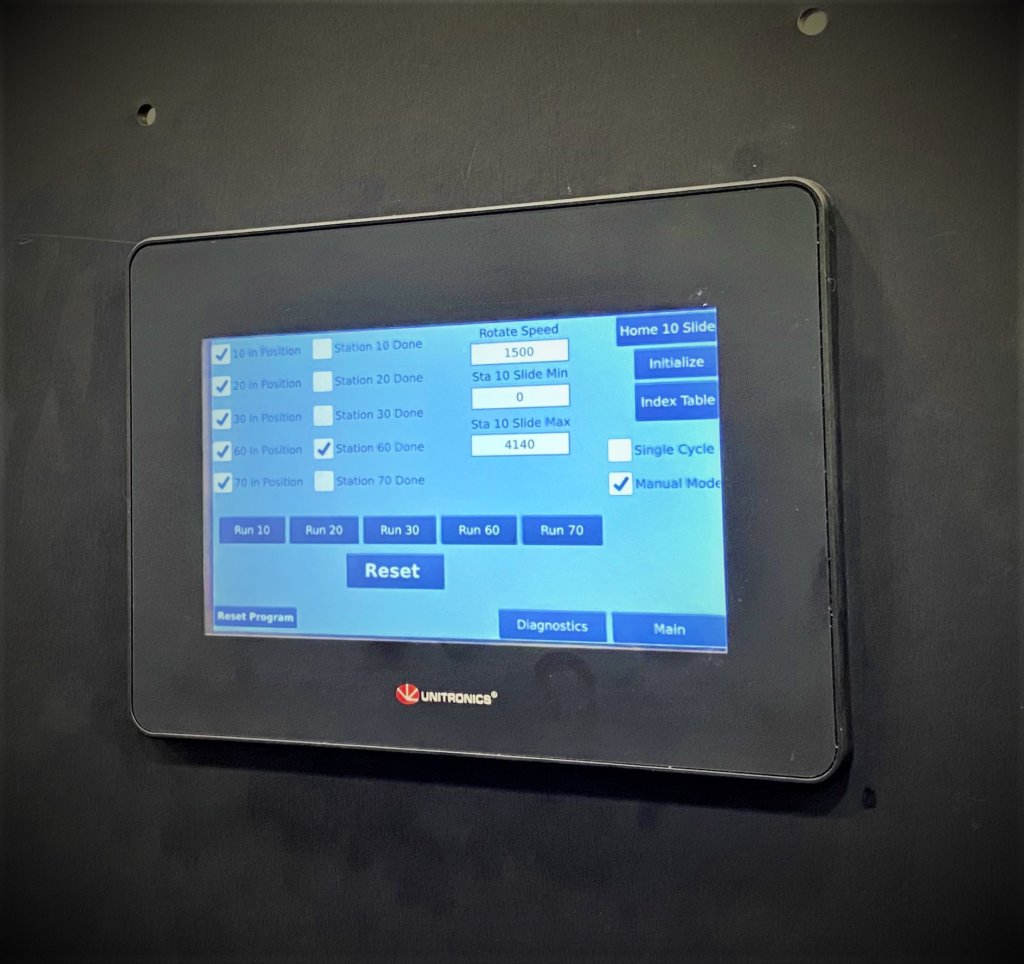

UniStream® 7″ Built-in: PLC Controller + HMI + I/O

A multi-function PLC with an integrated, high quality HMI touch screen, available in a range of built-in I/O configurations. The highly compact hardware profile, PLC+HMI+I/Os built into one unit, offers powerful control capabilities in an incredible space-saving configuration.

UniStream 7″ main features include Ethernet/IP, VNC, FTP, Web Server, Video + RTSP, SQL Client and more. It is backed by the most efficient programming software you have ever used.

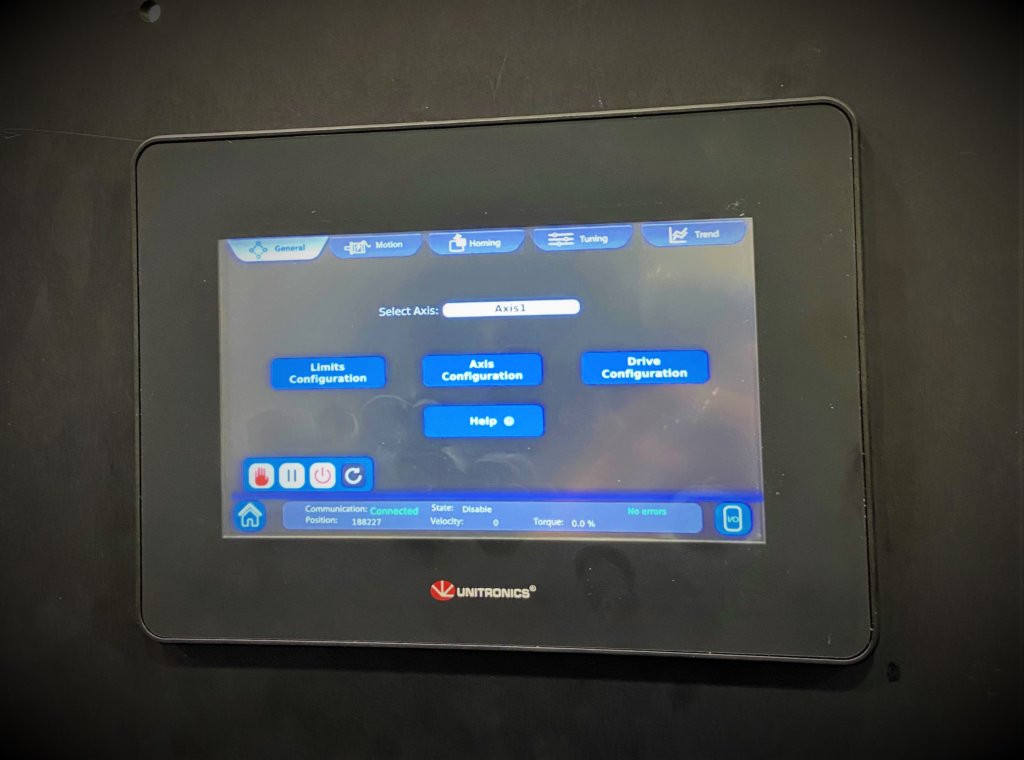

Unitronics AC Servo: Drives and Motors

Unitronics’ AC Servo Drives and Motors are transparently supported by UniStream controllers. The line includes 1 and 3-phase drives and motors, operating at a wide power range of 50W to 5,000W (0.06-6.7 HP) to suit any machine size, with robust, high-resolution built-in serial encoders (absolute: 23-bit, incremental: 20-bit), IP65.

Servo made simple has ready-made motion code enabling various capabilities. The built-in system integration capabilities let you perform any number of tasks at the tap of a screen, even from your mobile device! Unitronics provides you with system-wide control and visibility. You can tune your motion performances using a single parameter and view servo runtime performance via Unitronics software studio.

Unitronics One Solution has a single software for all PLC, HMI and motion aspects. This eliminates the hassle and struggle our customers have experienced with multiple software tools needed to build an application with up to 8 axes.

Customer Benefit

Unitronics’ integrated solution for control and automation offered an improved and simplified solution. Our customer receives value through ease of use in programming. They no longer have to configure a separate PLC or HMI and their new Servos integrate into the same software on the HMI + PLC.

One Integrated Solution is an easy way to avoid hassles, save time, and be confident that everything will work together exactly as you need it to, while still enjoying a wide choice of components and configurations.

Unitronics Servo Drives and Motors successfully delivered the precision and speed required to properly grip the rubber parts in this application.

With Unitronics novel control and automation solution you can rest assured that the components of your application will all work seamlessly together and with minimal effort.

At A-tech we have a high level of technical expertise that sets us apart from our competitors. We will find the application that is best for our customers automation needs and budget. Contact A-tech @800.225.6102