Track and Trace System Customer Application

Customer Challenge

A clothing distributor needs to check boxes of clothing for accuracy after they are filled. They are looking for an RFID solution that can be utilized on a conveyor. For example a box could have 10 socks, 40 shirts and 10 pairs of pants. They need a solution that will quickly tell them if the correct items and number of items are put into each box.

A-tech Solution

The experienced Automation Sales staff at A-tech were able to solve our customers challenge with a Track and Trace RFID solution. The track and trace system features interrogators for RFID identification, a central controller or computer with integrated assignment algorithm and barcode scanners that determine what objects should be in each box.

At our clothing distributor, clothing is put into boxes and a barcode is attached to each box that indicates which clothing should be in that box. After the clothing is added into a box it moves down the conveyor and goes through the track and trace RFID tunnel to check the contents of each box. On the outside of the tunnel is a CLV630 Barcode Scanner that reads the barcode on the outside of the box. The centralized computer used in this application was the WAGO Edge Computer. The Edge in this application was used as a Linux computer that was programmed in Node-RED. Through this custom programming we were able to communicate with the customers DB2 database for product information.

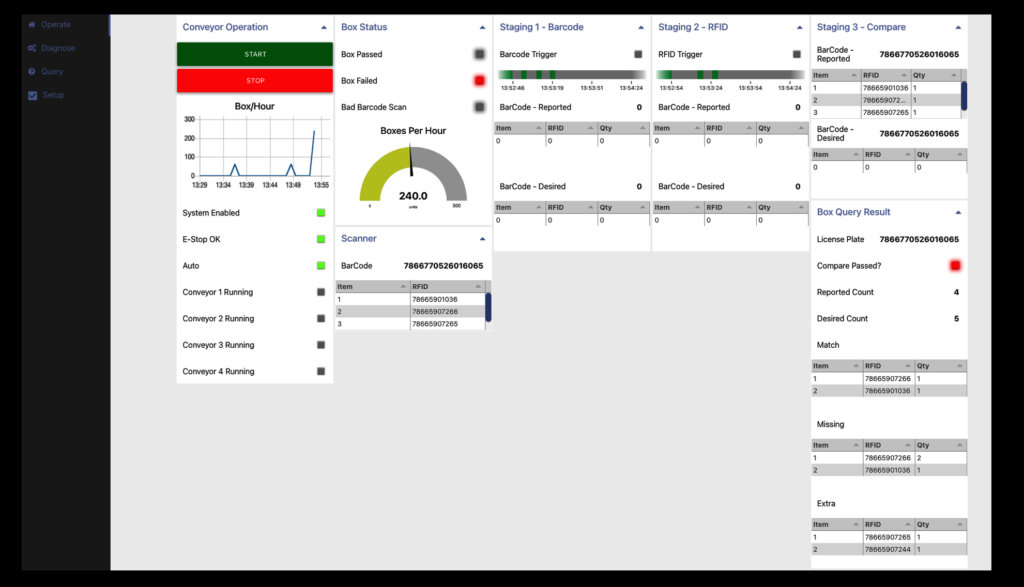

The Edge communicates between the barcode scanner and the RFID tunnel. Once the barcode is read the Edge pulls, from our customers D2B database, what the contents of the box going through the tunnel are. Then there are 3 RFU630 RFID scanners, one placed on the top and each side, in the tunnel. The RFID scanners report a list of products that were found in the box to the Edge. The WAGO Edge Computer cross references what the box barcode says should be in that box, with the product tags the RFID scanner picked up. If the box passes inspection, then it continues on the conveyor. If the box is found to be incorrect or incomplete it is pushed off the conveyor for manual inspection.

Additionally, a screen is mounted on the control panel that shows the Node-RED dashboard with what the contents of the box should be and what is found in real time. This can be monitored by plant staff or the reports can be viewed after.

Customer Benefit

Previously, our customer did not have a way to check the contents of a box that was not manual. The innovative module design of the track and trace makes it possible to quickly check the accuracy of boxes of clothing and this results in complete transparency in the supply chain. Beyond the supply chain advantages, this creates huge benefits in efficiency and saves a great deal of employee time. Our customer has multiple applications and was so happy with their result that they have applied the RFID tunnel at all locations.

The track and trace flexible module design makes it simple to change the mechanical setup for various logistics applications. Contact A-tech if you would like to know more about how track and trace can help you and your supply chain. Contact A-tech @800.225.6102