The WAGO CAGE CLAMP® Difference

What is the CAGE CLAMP® and how is it different from other screwless systems?

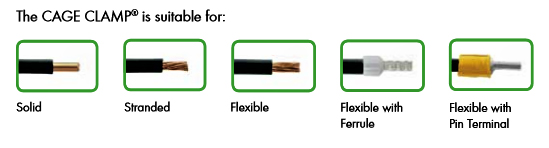

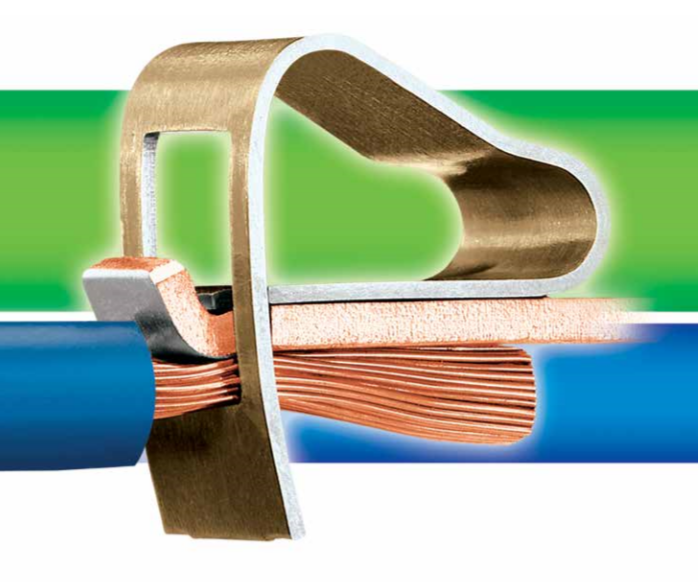

CAGE CLAMP® is a unique, patented, stainless steel clamping mechanism designed to automatically connect solid or stranded wire. Various CAGE CLAMP® sizes are available to accommodate wire sizes AWG 28-2. Other than stripping the wire, no special wire preparation such as crimps, ferrules or tinning is necessary.

Most screwless systems offered by other manufacturers are based on the leaf-spring principle. This type of connection is found in the back of many electrical outlets. Leaf-spring is only recommended for larger, solid wire since it has no sides to contain the strands and because of the sharp angle in which the wire is contacted.

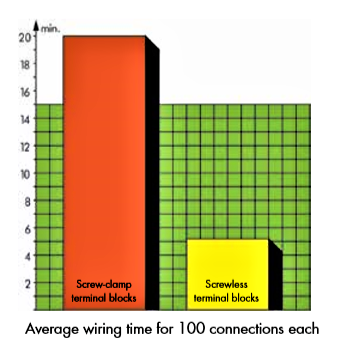

How does the wiring time for CAGE CLAMP® compare to screw-clamp blocks?

Public wiring competitions and major customer time studies have proven a reduction of wiring time by 75% when comparing manual wiring of screw-type terminals with CAGE CLAMP® terminals.

Even when powered screwdrivers are used for tightening the clamping screws, there is still a time savings advantage for CAGE CLAMP®. CAGE CLAMP® requires no special tools and is operated with a standard straight-bladed screwdriver. Two styles of terminal blocks are available: side-entry and front-entry.

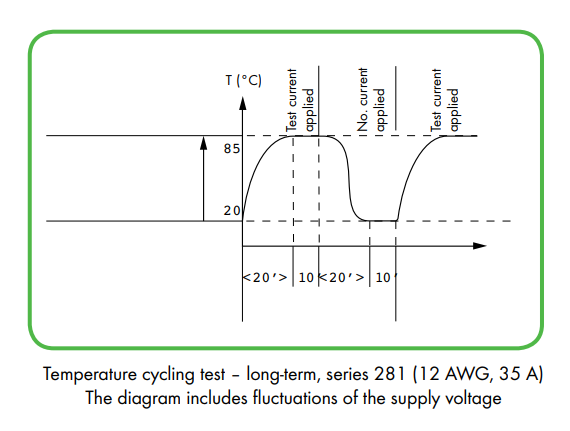

What effect does long-term temperature cycling have on the CAGE CLAMP® connection?

The voltage drop of a connection can change significantly over time, especially when changes in temperature exist. The heating and cooling expand and contract the contact parts, varying the contact pressure and deforming the wire. If this is not compensated for (i.e.: screws tightened) the contact will have a progressively higher voltage drop which can eventually impede the signal or cause arcing. CAGE CLAMP® automatically adjust for settling strands and changes in wire size. As illustrated by the results of this temperature cycling test, the voltage drop remains virtually constant – insuring long-term reliability.

The CAGE CLAMP® is computer designed for maximum reliability. Springs under permanent dynamic load, such as automobile and industrial springs work reliably and perform millions of operations during their lifetime. By comparison, the CAGE CLAMP® is typically operated only a few times and yet it is designed according to the same principles as springs under dynamic load.

WAGO has over forty years experience in the design and manufacture of high quality connections. State-of-the-art quality control insures that these high standards are maintained.

To discuss how WAGO 221 Series splicing connectors can help your company, contact us at (800) 225-6102 or sales@atech-inc.com