IO-Link opens the door to the IIoT

Overall Landscape

The majority of sensors and actuators today are already equipped with microprocessors, which can be used for parameterization, storing configuration data and controlling indication. The natural next step is to overcome the bottleneck of the binary standard interface and make additional functions centrally accessible for the automation system.

Due to this, a lot of well-known manufacturers from the field of automation have come together and developed a fieldbus independent communication interface for sensors and actuators, know as IO-Link. To guarantee Investment protection, compatibility with existing technologies was the primary objective during IO-Link development.

What is IO-Link?

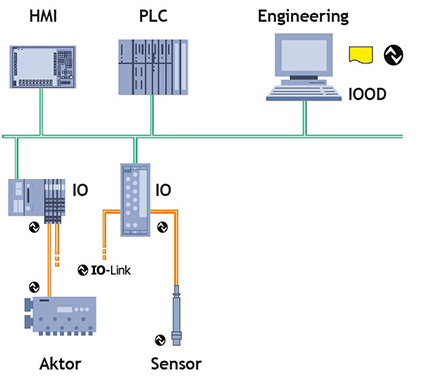

IO-Link (IEC61131-9) is an open standard serial communication protocol that allows for the bi-directional exchange of data from sensors, actuators and devices that support IO-Link and are connected to a master. The IO-Link master can transmit this data over various networks, fieldbuses, or backplane buses, making the data accessible for immediate action or long-term analysis via an industrial information system (PLC, HMI, etc.). Each IO-Link sensor has an IODD (IO Device Description) file that describes the device and its capabilities.

It should be noted that IO-Link is not another fieldbus, but rather a point-to-point communication protocol between a compatible IO system and a field device. Because IO-Link is an open standard, devices can be integrated in virtually any fieldbus or automation system.

Common Misconceptions on IO-Link

IO-Link’s advanced features and functionality, from parameter storage to detailed diagnostics, have generated plenty of enthusiasm. However, this intensive focus has created the common misconception that advanced capabilities are the only reasons to implement this technology.

The primary goal of IO-Link is to improve sensor or field-level device communication capabilities through a standardized interface. This goal is not only relevant for complex installations or operations. It is also useful for simpler applications found in many automated systems.

Engineers often implement IO-Link to improve essential functions such as data processing. They can also achieve higher I/O density, standardize interface technology and improve capabilities compared to traditional I/O systems.

While it is now possible to implement this technology in most modern automated control systems, not every application is an ideal fit. By understanding IO-Link, both its capabilities and its limitations, automation systems engineers can decide if it is a worthwhile investment for their company.

When IO-Link may not be right for your organization

While IO-Link offers numerous benefits for many industrial applications, there are situations where existing solutions fit better. For example, simple standalone applications might not greatly benefit from the features of IO-Link. If your current solution is delivering the data and operational capabilities you need, you likely will not see a large benefit from switching to IO-Link. Applications that require specialty sensors are another example, as IO-Link has not expanded to all sensors yet. Your current solution may be a better choice if you are getting the data you need.

5 Advantages of IO-Link

There are many advantages of an IO-Link system including standardized and reduced wiring, increased data availability, remote configuration and monitoring, simple device replacement and advanced diagnostics.

Together these capabilities result in:

Overall reduced costs

Increased process efficiency

Improved machine availability

The benefits of IO-Link are especially significant in applications in that experience frequent changeover and are severely impacted by extended and/or unplanned downtime.

1. STANDARDIZED AND REDUCED WIRING

A critical benefit of IO-Link for many industries is that it does not require any special or complicated wiring. Rather, IO-Link devices can be connected using the same cost-effective standard unshielded 3-wire cables as conventional discrete I/O, which helps keep wiring simple. In addition, IO-Link also eliminates the need for analog sensors and reduces the variety of cord sets required for sensors, which saves inventory costs.

2. INCREASED DATA AVAILABILITY

Data availability is a powerful advantage of IO-Link that has broad implications. Access to sensor-level data helps ensure the smooth operation of system components, streamlines device replacement, and enables optimized machine maintenance schedules. All of the following save costs and reduce the risk of machine downtime.

There are three primary data types made available via IO-Link communication, which are categorized as either cyclic data (data automatically transmitted on a regular basis) or acyclic data (data transmitted as needed or upon request).

Process Data refers to the information that the device reads and transmits to the master. The distance reading on a laser measurement sensor is an example of process data. Process data can also refer to information that is transmitted to the device from the master (such as messages sent to a tower light indicating which color segments should be illuminated). Process data is transmitted cyclically in a defined data frame. In addition, value status data (indications of whether or not process data is valid) is transmitted along with process data.

Service Data, also known as Device Data, refers to information about the sensor itself such as parameter values, model and serial numbers, device descriptions, etc. Service data can be both written to the device or read from the device acyclically.

Event Data refers to notifications such as error messages or maintenance warnings (ex. dirty lens, device overheating) that are transmitted acyclically from the IO-Link device to the master whenever an event occurs.

3. REMOTE CONFIGURATION AND MONITORING

IO-Link users can read and change device parameters through the control system software, enabling fast configuration and commissioning that saves time and resources. In addition, IO-Link allows operators to dynamically change the sensor parameters from the control system as needed, such as in the case of product changeover, which reduces downtime and allows machines to accommodate greater product diversity. This is especially important in consumer-packaged goods applications where the demand for variety in packaging is continually increasing.

Furthermore, the ability to monitor sensor outputs, receive real-time status alerts, and adjust settings from virtually anywhere allows users to identify and resolve problems that arise on the sensor level in a timely manner. This also means that users can make decisions based on real-time data from the machine components themselves, which can reduce costly downtime and improve overall efficiencies.

4. SIMPLE DEVICE REPLACEMENT

On top of the ability to remotely adjust sensor settings, IO-Link’s data storage capability also allows for automated parameter reassignment in case of device replacement (this functionality is also known as Auto-Device Replacement or ADR). Users can import existing sensor parameter values into a replacement sensor for seamless replacement, getting the new device up and running as fast as possible.

5. EXTENDED DIAGNOSTICS

IO-Link provides users with visibility into errors and health status for each device. This means that users can see not only what the sensor is doing but also how well it is performing. This is a valuable insight into a machine’s efficiency. Additionally, extended diagnostics allow users to easily identify when a sensor is malfunctioning and diagnose the problem without shutting down the line or machine.

The combination of both real-time and historic data made available via an IO-Link system not only reduces troubleshooting efforts as issues arise but also allows for optimization of machine maintenance schedules, saving costs and increasing efficiency in the long term.

IO-Link is key to IIoT

A key to making the Industrial Internet of Things (IIoT) and smart factories a reality is the two-way communication that IO-Link provides between low-level sensors and actuators and higher-level controllers and automation systems. This wealth of valuable data combined with vendor independence and interoperability, make IO-Link a significant tool for successfully implementing IIoT and Industry 4.0.

To discuss how IO-Link can help your company improve data communication, contact us at (800) 225-6102 or sales@atech-inc.com. To learn more, check out a few of our manufacturers IO-Link educational videos below.