Automation Application for Chemical Blending and Transferring

Customer Challenge

An A-tech customer that manufactures and distributes Industrial Food and Specialty Chemicals needs a faster and more accurate way to mix and blend different chemical combinations, as well as the accurate filling of replenishment tanker chemical trucks with minimal straight runs of pipe. The customer is currently using the GF+ Signet 2551 Magmeter Flow Sensor. The 2551 is an insertion-style magnetic flow sensor. They are also currently measuring the chemicals based on weight, and manually starting and stopping the batch when it reaches a certain weight, to achieve the blending of chemicals at desired consistencies.

A-tech Solution

The experienced Automation experts at A-tech were able to find a solution within our Industry leading manufacturers new and existing products. The combination of the GF+ Signet 9900-1BC Batch Controller System, the NEW GF+ Signet 2580 FlowtraMag™ Meter and the Georg Fischer Actuated valve was the winning solution.

Our customer uses several different chemicals in their production of Industrial Food and Specialty Chemicals. The chemicals can be aggressive and are normally stored in tanks at their facility. There are multiple applications at our customers facility where they are utilizing the batch controller, valve and flow meter combo that we have designed.

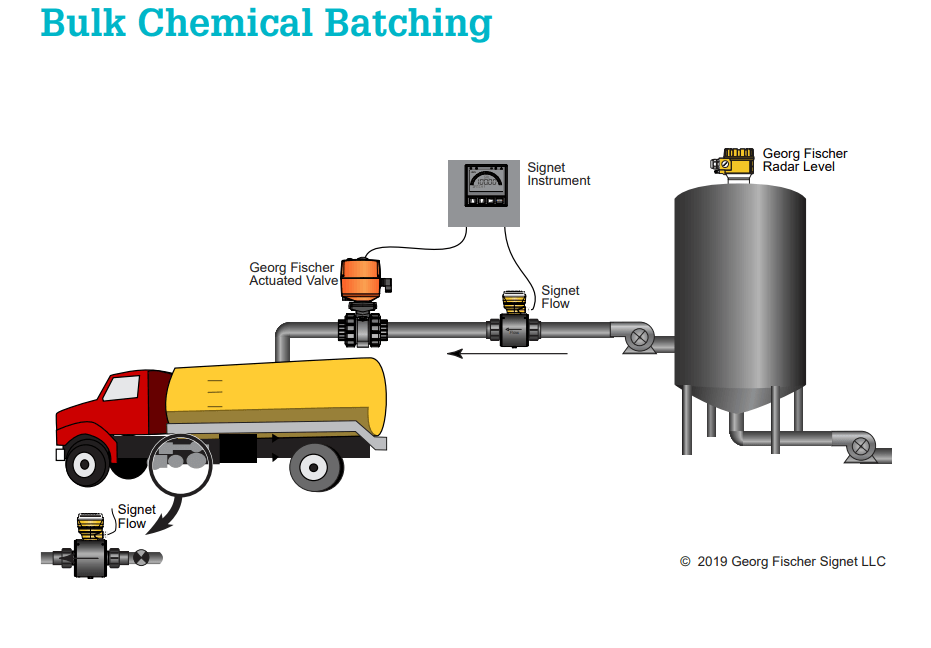

Application 1. When the chemical storage tanks become depleted, they need to be filled by tanker trucks that deliver replenishment chemicals

Application 2. Used in the creation of the end product by controlling and automating the mixing and blending ratios of different chemicals into one tank.

Application 3. When the finished product chemicals have been created, they need to be transferred to the tanker trucks and transported to the end user.

Let’s walk through how our customer utilizes the new GF combination from application 3.

A tanker truck pulls into the depot where an operator attaches a hose to the truck‘s tank. A 9900-1BC Signet Batch Controller is set with a predetermined batch. It is being fed a flow signal from the Signet 2580 FlowtraMag.

The controller is also tied into a Georg Fischer automated valve. When the start button is pushed on the 9900-1BC, the valve opens and the chemical pump starts sending the end product chemicals to the tanker truck.

The batch is now under way. With the 2580‘s high accuracy (±1% of reading) even when placed within 3 pipe diameters away from an obstruction, the system will provide an accurate batch of the desired chemical to the tanker truck. At the end of batch, the 9900-1BC signals the valve to close and the pump to stop. An accurate batch of chemical has now been transferred to a tanker.

Customer Benefit

The customer was previously using an insertion flow meter and manually starting and stopping chemical transfers based on weight measurement. Eliminating the manual components of the process with the 9900-batch controller has increased production efficiency. Switching to the FlowtraMag flow meter with a higher accuracy certification of ±1% of reading, compared to the ±2% accuracy of the Signet 2551 Insertion flowmeter, ensured further precision in their production process. The Signet 2580 FlowtraMag™ magnetic flow meter when being used with the Signet 9900-1BC batch controller, combines for a highly accurate yet economical solution for bulk chemical delivery to chemical trucks and in the manufacturing of chemicals through chemical tank blending. The 2580 FlowtraMag’s ability to measure accurately with minimal straight runs of pipe, means the user can fit these flow sensors in more confined areas. Add in a Georg Fischer Actuated valve and you have a complete batch control system.

Learn More about the FlowtraMag™ Meter and the 9900-1BC Batch Controller

Signet 2580 FlowtraMag™ Meter

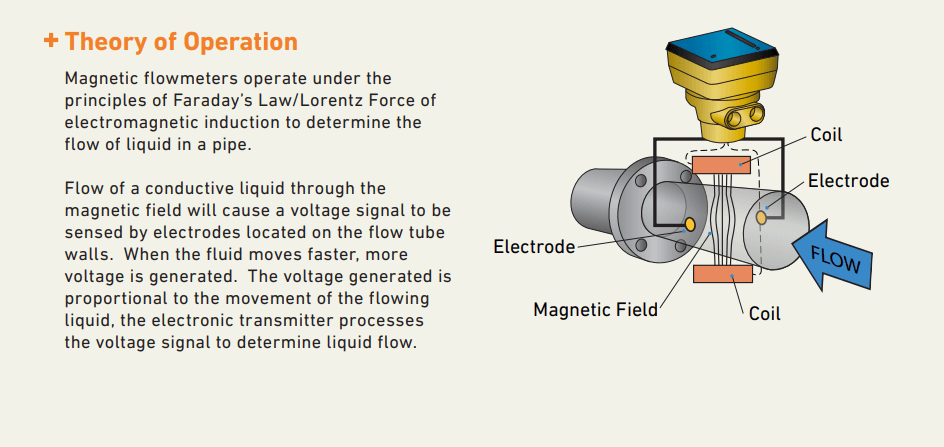

The NEW Signet 2580 FlowtraMag™ Meter is a full-bore plastic in-line style magnetic flowmeter. The PVC body with titanium electrodes has no moving parts, and is two to three times lighter in weight compared to traditional metal magmeters on the market. It is designed for high accuracy flow measurement in short pipe runs. Users can configure and calibrate the 2580 using the GF Configuration Tool Bluetooth® App.

+ Features & Benefits – Signet 2580 FlowtraMag™ Meter

- • No moving Parts

- • Lighter in weight compared to traditional metal magmeter

- • Reduced straight run requirements, ideal for final effluent lines, wellheads and skids

- • Factory calibrated with certificate (±1% of reading accuracy)

- • Partially filled pipe status indicator

- • Reverse flow direction configurable with 0252 Configuration Tool or GF Config Tool Bluetooth® App

- • One device with 3 different outputs: field selectable Frequency or Digital (S’L). and analog 4 to 20 mA

- • On-the-fly configuration with GF Config Tool Bluetooth® App

Signet 9900-1BC Batch Controller System

The Signet 9900-1BC Batch Controller System provides control capability and process fine-tuning in a familiar package. The programming interface uses a four-button keypad and an intuitive menu for adjusting a batching system to the best performance possible. Choose between simple or advanced modes. In simple mode, relay outputs can be used for batching, external counter, missing signal alarm and 4 to 20 mA output can be used to indicate batch status. In advanced mode, relays can also be used for end of batch pulse, two-stage shutdown, overrun alarm, high flow detection, total volume or source volume alarm.

Designed for a variety of batch applications, the 9900-1BC Batch Controller System can save up to 10 batch sizes for batching or blending a variety of liquid volumes. Customize batch names for easy distinction between batches. One K-Factor can be used for all batches, or use a different K-Factor for each batch for when different liquids are batched. The user can choose to be prompted prior to starting a batch with a Yes/No or with a password to prevent inadvertently starting a batch.

The 9900-1BC Batch Controller System operates on 10.8 to 35.2 VDC, regulated. Connect a remote start or stop switch for remote batch control. Use the end-of-batch pulse to trigger the next step in the process.

At A-tech we have a high level of technical expertise that sets us apart from our competitors. We will find the application that is best for our customers automation needs and budget. Call A-tech @800.225.6102