Automated Quality Control for Plastic Molded Parts

Customer Challenge

A Plastic Molded Parts manufacturer needs an automated solution to check quality control on a custom part. They need to ensure two metal rings, one rubber ring and the part barcode have been correctly installed. Currently they have employees doing quality control, but find many parts get by that should fail inspection. They would like an automated solution that reduces the number of parts that incorrectly pass manual inspection and keeps a log of the pass/fail rates.

A-tech Solution

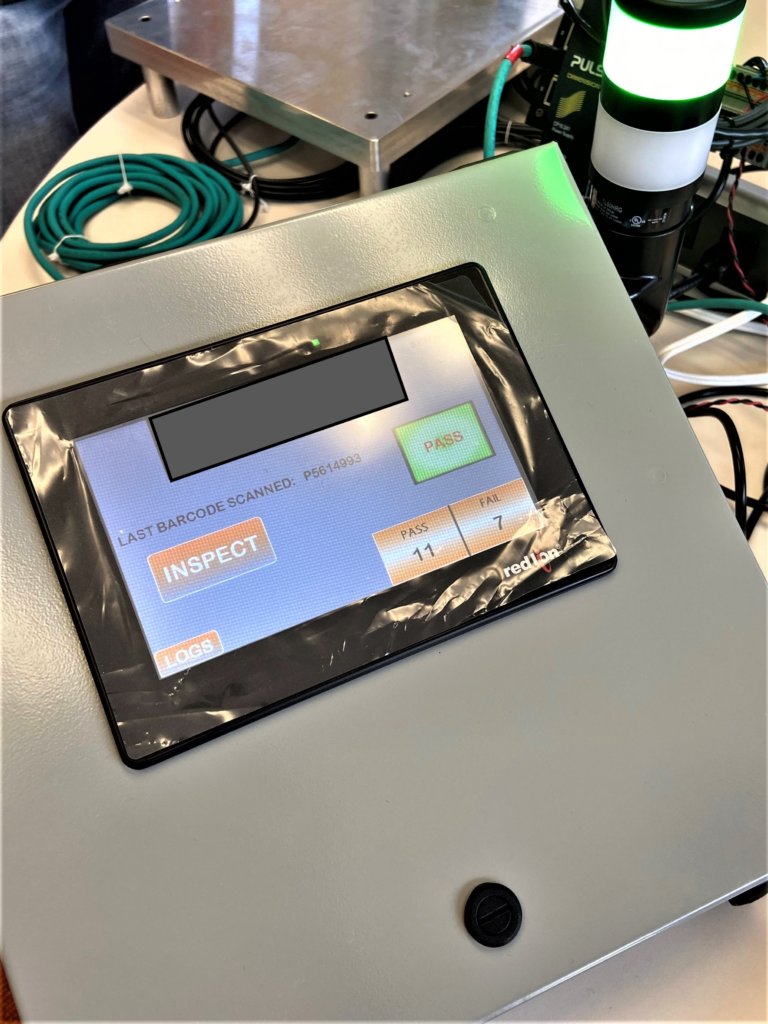

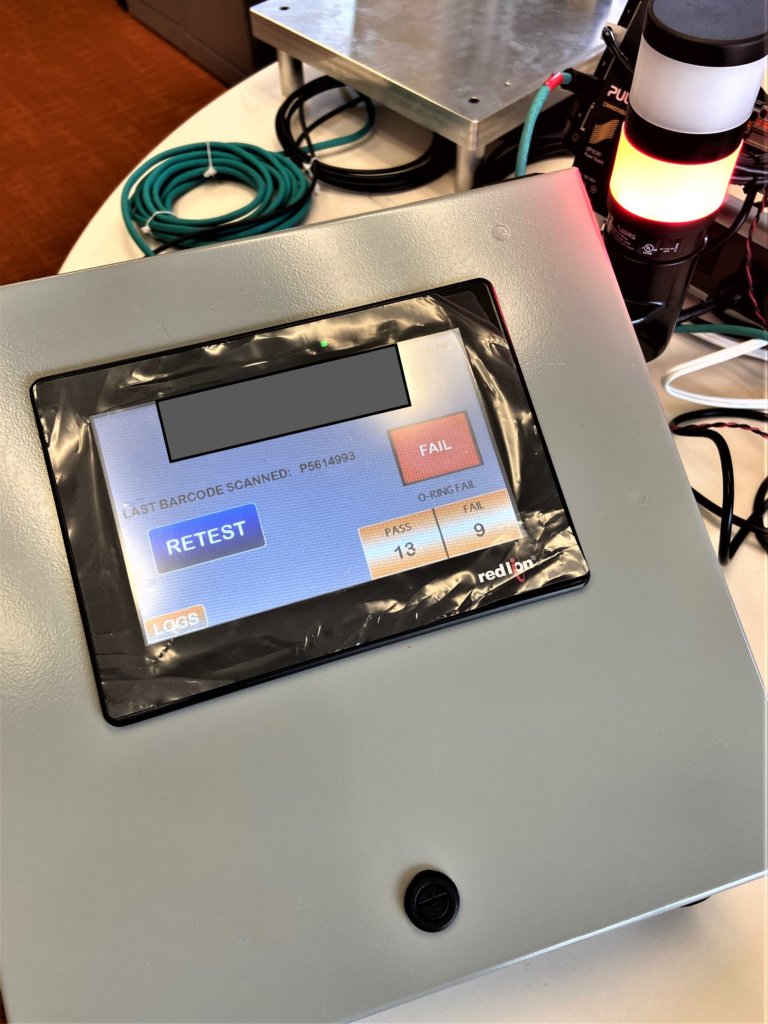

The experienced Automation Sales staff at A-tech were able to find the best multi-vendor solution for our customer. A complete quality control solution starting with a Red Lion Controls 7” CR3000-07000-00420 HMI touchscreen mounted on a control box. The HMI touchscreen inspection button is pressed when a part is ready for inspection and the screen shows a green pass box or a red fail box, once the sensors mounted strategically around the part, report back if they detected the two metal rings, one rubber ring and the correct barcode.

After the inspection is triggered the part is locked in place and only unlocked once it receives a passing status. If a part fails, it stays locked until there is a manager override and the part is removed from production. To make the pass/fail status even more evident to the user, a Banner TL50 Core series high-intensity tower light is installed on the control box. The tower light turns green when a part passes and red when it fails.

The sensors used if this application were strategically mounted, at our customers facility, where the parts is placed for inspection. For the sensors, A-tech used a photoelectric laser distance sensor to detect if the rubber ring was installed and two Proximity sensors to detect the presence of the two metal rings. Lastly, the SICK Lector620, an image-based code reader, reads the part number barcode during inspection. In order to receive a passing status, the correct barcode for the part must be found by the Lector620 and reported back to the HMI.

Customer Benefit

Our customer got a user-friendly solution that reliably detects if the parts pass or fail inspection and reports which part numbers passed or failed. This helps our customer ensure failed parts don’t get missed by manual inspections and sent out to their customers. Helping them avoid costly returns and customer dissatisfaction.

At A-tech we have a high level of technical expertise that sets us apart from our competitors. We will find the application that is best for our customers automation needs and budget. Contact A-tech @800.225.6102