Take automation to the next level with Robot Vision and Guidance

Customer Challenge

An Oil Field Services customer needs a vision solution for their KUKA robot. The robot needs to be able to see which slots in the nest have tubing in them so it can pick them up. The robot will move the tubing one at a time into the induction heater to be coated. After the induction heater, the robot will take the tubing to the oven where the tubing is gradually cooled to the desired temperature. Lastly, the robot needs to remove the tubing from the oven and put it back into an empty nest. The current process for doing this is manual and the customer is not able to produce as many finished tubes a day as the demand requires. They have a acquired a robot to automate this process but need the proper robotic vision to solve their tubing production challenge.

A-tech Solution

Robot Vision: SICK Visionary-T

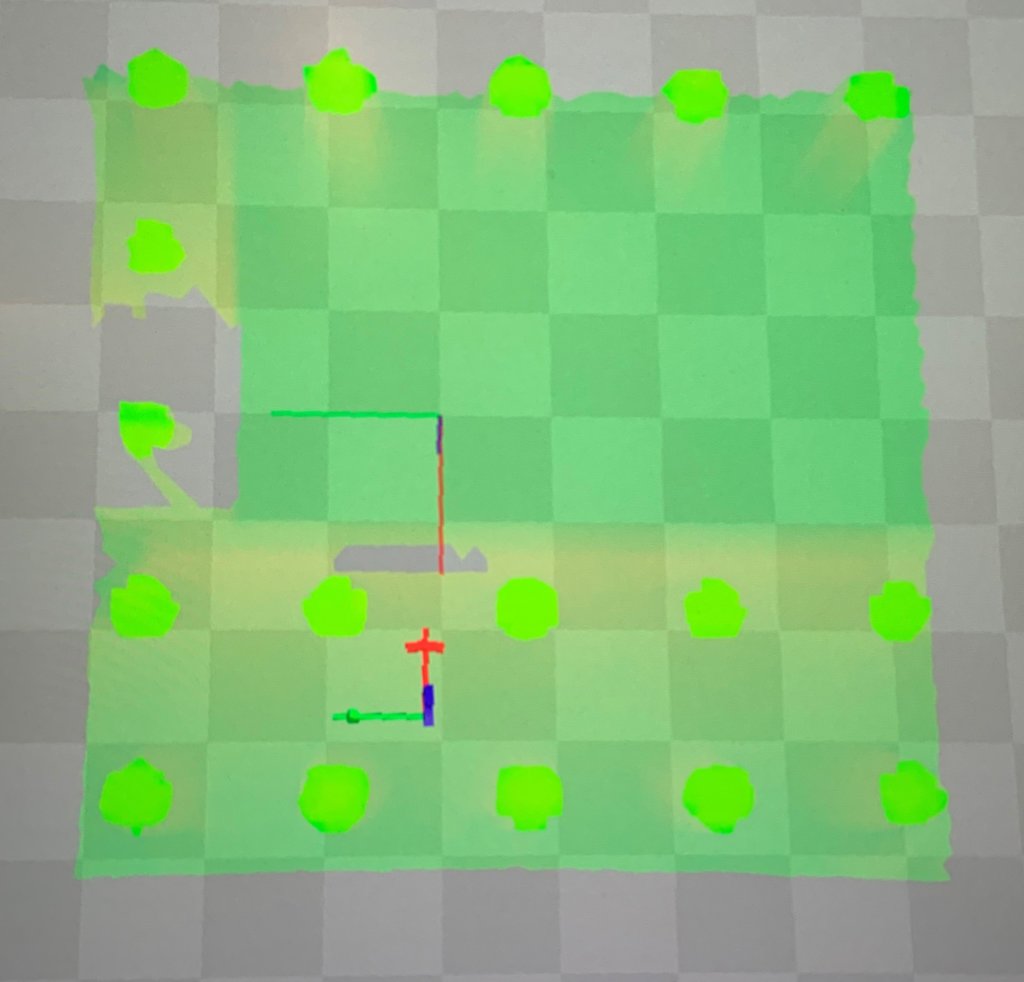

The experienced Automation Sales staff at A-tech were able to find the right Robotic vision solution for our customer. The solution starts with the SICK Visionary-T DT 3D camera. The Visionary is placed high above the robot and it gives an overall view of the tubing nest. The Visionary allows the robot to identify the nest and where the tubes are located inside of the nest. It then counts/assigns numbers to the tubing in the nest.

Visionary-T cameras are easy to set up with SOPAS ET software with teach in scene capability. This camera can solve several detection tasks within one configuration. The Visionary-T can store and switch between 30 different configurations.

- • 3D detection sensor for indoor use

- • Easy and intuitive setup via SOPAS ET and teach-in function

- • Stand-alone device

- • Smart detection algorithm

- • Detection signals via digital outputs, control via digital inputs

Robot Guidance: Inspector PIM60

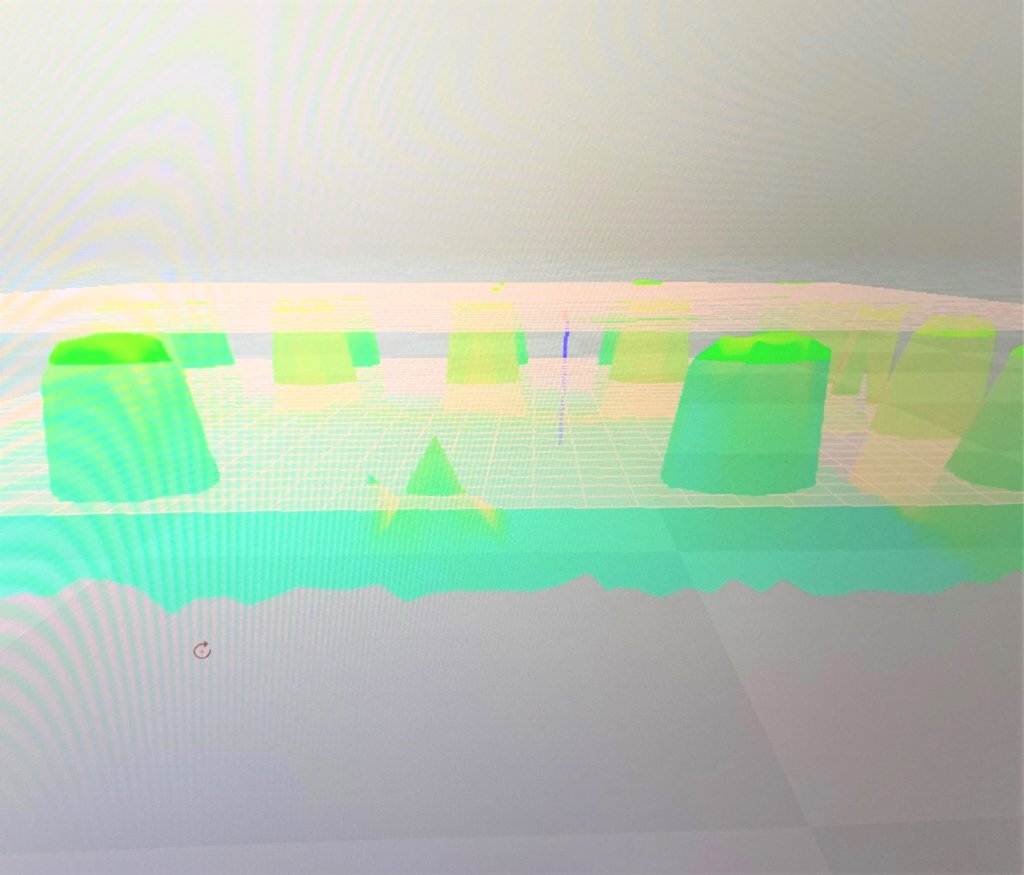

The second part of our Robotic vision solution is the SICK Inspector PIM60 2D camera used for pick and place robot guidance. After the Visionary 3D camera has communicated with the Robot on where the nest is and the count in the nest, then the Inspector PIM60 is placed on the robot itself as its eyes and used to instruct the robot on the coordinates of where to pick up each tube. The Inspector will register if the nest gets moved even slightly by external factors and it needs to adjust the coordinates for each tube. The PIM60 takes snapshots that help guide the robot as it picks up the tubing and moves it from the nest to the induction heater, then into the oven for gradual cool down and then finally back into an empty nest as a completed product.

This vision solution sensors’ rugged design and IP 67 metal housing makes it ideal for tough environments and intelligent processing technology makes the Inspector perfect for high-speed applications. The flexible housing is designed to easily optimize the optical needs of your application. This ensures excellent inspection even with tough targets, such as highly reflective metal parts and multicolored labels.

- • High-speed positioning, inspection and measuring

- • Powerful “object locator” tool, independent of position, rotation and scale

- • Unique, interchangeable housing design supporting dome and various optical accessories

- • Simple step-by-step configuration in PC including emulator

- • Easy-to-use operator interfaces

- • Flexible machine and HMI design interfaces

Customer Benefit

The customers previous process was time consuming and manual. Consequently, they weren’t able to produce the volume of finished tubing that they desired in a day. With the addition of SICK Sensor Intelligence Robotic Vision solutions, not only was A-tech was able to help them automate that process to improve efficiency, it also yielded huge gains in the safety department. Employees that were once more hands on with the manual tubing production are now supervising the process from a safer distance.

At A-tech we have a high level of technical expertise that sets us apart from our competitors. We will find the application that is best for our customers automation needs and budget. Contact A-tech @800.225.6102